Gantry Crane

Gantry Crane Specification

- Crane Total Weight

- Approx. 3000 kg

- Trolley Travel Speed

- 15 m/min

- Feature

- Corrosion Resistant, Easy to Operate, Heavy Duty Design

- Crane Traveling Speed

- 20 m/min

- Condition

- New

- Recommend Power

- 10 kW

- Material

- Mild Steel

- Crane Type

- Gantry Crane

- Application

- Warehouses, Construction, Industrial

- Span Length

- 12 m

- Loading Capacity

- 5000 kg

- Lifting Capacity

- 5 Ton

- Lifting Height

- 9 m

- Control Type

- Pendant / Wireless Remote

- Limit Switch

- Provided

- Emergency Stop

- Yes

About Gantry Crane

AUTOLIFT is offering Gantry Cranes that are mainly used to handle heavy load containers. Extensively used in covered as well as in open areas, these gantry cranes can be assembled as per the application requirements at the clients end. These are highly suitable for overhead material handling of varied capacities. Our cranes are provided with a main girder that is mounted on two A-shape columns, which rest on wheel mounted end carriages. The main girder of the system is designed by considering each detail of the class, the frequency of operation & the duty cycle. The types of girders that we are offering are RSJ type, plate box type or truss type for single girder with its bottom flange as path for trolley of hoist. Further, these can also be provided with double girder design that suits the heavy duty applications, where a suitable track is provided on top of the girders for travel of crab wheels.

Generally these Cranes are used at :

- Ship Yards

- Ports.

- Granite & Marble cutting and polishing Industries

- Comet Pipe Industries

- Open yard Storage Places

- Container Depute.

The name Goliath indicates its Huge Load Capacity and giant structural built up. However some time finds its place in assembly shop of Engineering unit Specifically in Automobile Unit.

Heavy-Duty Construction for Demanding Environments

Built from premium mild steel and equipped with corrosion-resistant components, this gantry crane offers remarkable longevity and resilience even in tough industrial settings. Its robust structure ensures safe and stable handling of heavy loads, making it ideal for continuous operations in warehouses and construction sites.

Efficient Operation and Versatile Control

Designed with user convenience in mind, the crane can be operated via pendant or wireless remote, allowing for flexible and precise control across its 12-meter span. Swift movement is guaranteed by impressive traveling (20 m/min) and trolley (15 m/min) speeds, streamlining the process of material transfer and load positioning.

Safety Features You Can Trust

Safety comes first with this gantry crane, featuring reliable limit switches and a dedicated emergency stop mechanism. These built-in safeguards minimize risk, protecting operators and materials during all lifting procedures, making this crane a secure addition to any industrial workspace.

FAQs of Gantry Crane:

Q: How is the gantry crane operated and controlled?

A: The gantry crane can be managed through either a pendant or a wireless remote, providing operators with flexibility and precise maneuvering during load handling tasks. This dual control system enhances convenience and safety in various working conditions.Q: What are the primary benefits of using this 5-ton gantry crane?

A: This crane offers a combination of heavy-duty design, corrosion-resistant materials, and user-friendly operation. It delivers reliable lifting performance up to 5000 kg, efficient movement speeds, and essential safety features, maximizing productivity and reducing operational risks.Q: What safety mechanisms are integrated into this crane?

A: Safety is addressed through limit switches, which prevent overtravel, and an emergency stop feature that allows operators to halt operations instantly if necessary. These components help safeguard both personnel and equipment during lifting activities.Q: Where is this gantry crane typically used?

A: This gantry crane is ideal for use in warehouses, construction sites, and various industrial environments, especially where heavy material handling over a wide span and significant height is required.Q: How does the crane resist corrosion in tough environments?

A: The crane is fabricated from mild steel with a corrosion-resistant finish, providing robust protection against harsh environmental factors and extending the equipments operational lifespan.Q: What is the process for installing and commissioning this crane?

A: Installation and commissioning are handled by professional technicians, ensuring correct assembly, safety checks, and the set-up of control and power systems for smooth and safe operation from day one.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Cranes Category

Tower Crane

Crane Type : Other Cranes, Tower Crane

Application : Other, Construction, Building, Infrastructure

Material : Steel

Condition : New

Loading Capacity : Max 6 Tons

EOT Crane

Crane Type : Other Cranes, Electric Overhead Traveling (EOT) Crane

Application : Other, Industrial Material Lifting, Warehouses, Workshops, Factories

Material : Mild Steel

Condition : New

Loading Capacity : 10 Ton

Single Girder Gantry Crane

Crane Type : Other Cranes, Single Girder Gantry Crane

Application : Other, Material handling and lifting

Material : Highgrade steel

Condition : New

Loading Capacity : Up to 10 tons

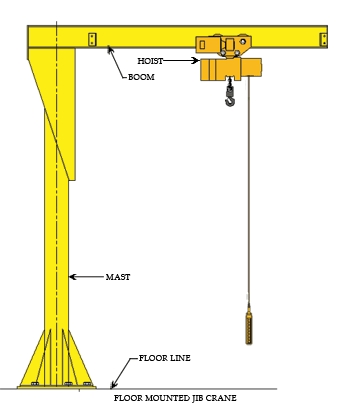

Jib Crane

Minimum Order Quantity : 10 Pieces

Crane Type : Jib

Application : Warehouse, Construction

Material : Mild Steel

Condition : New

Send Inquiry

Send Inquiry