EOT Crane

EOT Crane Specification

- Feature

- High Durability, Corrosion-Resistant, Robust Construction, Smooth Operation

- Trolley Travel Speed

- 14 m/min

- Crane Total Weight

- Approx. 8,500 kg

- Condition

- New

- Crane Traveling Speed

- 20 m/min

- Recommend Power

- 15 kW

- Material

- Mild Steel

- Crane Type

- Electric Overhead Traveling (EOT) Crane

- Application

- Industrial Material Lifting, Warehouses, Workshops, Factories

- Span Length

- 15 Meter

- Loading Capacity

- 10 Ton

- Lifting Time

- Depends on Load & Height

- Lifting Capacity

- 10 Ton

- Lifting Height

- 8 Meter

- Control Type

- Pendant Control / Remote Control

- Limit Switch

- Yes

- Emergency Stop

- Yes

- Operation Method

- Floor / Cabin / Remote

- Hoist Type

- Electric Wire Rope Hoist

- Maintenance

- Easy and Low Maintenance Design

- Beam Type

- Single/Double Girder

- Installation

- On Request

- Power Supply

- 3 Phase, 415V, 50 Hz

- Painting

- High Quality Anticorrosive Paint

- End Carriage

- Fabricated Box Type

- Noise Level

- Low

About EOT Crane

EOT Cranes, also known as electric overhead traveling cranes, are one of the most often utilized types of lifting equipment in various industries' workshops, warehouses, and storage yards. The overhead crane can make full use of the space under the bridge due to its distinctive structure, allowing it to lift goods from the ground without impediment. The EOT crane is an instrument and piece of equipment in the current industrial production and transportation process, such as in the iron and steel industry, railway transportation, port terminals, logistics, and other departments and places.

Specification

| Span Length | 30 m |

| Power Source | Electric |

| Load Capacity(Tons) | 40 Ton |

| Phase | Single |

| Frequency (Hertz) | 50 - 60 Hz |

| Voltage (Volt) | 220 V / 110 V |

| Material | MS |

| Hoist Travelling Speed | 10 m/min |

| Usage/Application | Industrial |

Reliable Industrial Lifting Solution

This EOT Crane is engineered for handling heavy materials in demanding environments. With a sturdy fabricated box end carriage and electric wire rope hoist, it delivers dependable performance and precise control, suited for a variety of industrial settings. The design ensures efficiency whether installed in a warehouse, workshop, or factory.

Superior Safety and Ease of Operation

Safety is prioritized through features like limit switches and emergency stops, while control options including pendant, remote, or cabin ensure flexible operation. The low-noise mechanism and smooth movements create a comfortable work environment, and the anticorrosive paint protects the crane from harsh conditions.

Durable, Low Maintenance Construction

Manufactured from mild steel with a robust design, this crane is built for longevity. The high-quality paint finish ensures resistance to corrosion, while the box-type end carriage and streamlined construction translate into minimal upkeep. The easy and low maintenance design contributes to reduced downtime and long-term reliability.

FAQ's of EOT Crane:

Q: How is the EOT Crane installed and what support is offered during setup?

A: Installation is available on request, with professional support provided by our team to ensure correct placement and optimal operation. We tailor the process to your facility's requirements and offer guidance on commissioning and safety testing.Q: What control methods are available and how do they enhance crane operation?

A: The crane can be operated via pendant control, remote control, or cabin, offering users flexible options to suit various work environments and operator preferences. These methods improve usability and safety for different tasks and setups.Q: What maintenance is required for this EOT Crane and is it difficult to maintain?

A: Designed for easy and low maintenance, the crane's robust construction and anticorrosive coating minimize upkeep. Routine checks and basic servicing such as lubrication and inspections are generally sufficient to maintain performance and extend service life.Q: Where can this type of EOT Crane be used effectively?

A: This crane excels in settings such as industrial warehouses, manufacturing facilities, and workshops where heavy lifting and material handling are essential. Its durable build and versatile beam options fit a wide range of industrial applications.Q: What are the main benefits of using an electric wire rope hoist in this crane?

A: The electric wire rope hoist offers reliable lifting with smooth and controlled movements, low noise levels, and high durability. It supports efficient handling of loads up to 10 tons, making it ideal for demanding lifting operations.Q: How does the anticorrosive paint contribute to the crane's performance?

A: The high-quality anticorrosive paint protects the crane's mild steel surfaces from rust and weather-related damage, extending its operational lifespan and ensuring consistent, safe performance in harsh industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Cranes Category

Tower Crane

Material : Steel

Condition : New

Application : Other, Construction, Building, Infrastructure

Crane Type : Other Cranes, Tower Crane

Loading Capacity : Max 6 Tons

Gantry Crane

Material : Mild Steel

Condition : New

Application : Other, Warehouses, Construction, Industrial

Crane Type : Other Cranes, Gantry Crane

Loading Capacity : 5000 kg

Single Girder Gantry Crane

Material : Highgrade steel

Condition : New

Application : Other, Material handling and lifting

Crane Type : Other Cranes, Single Girder Gantry Crane

Loading Capacity : Up to 10 tons

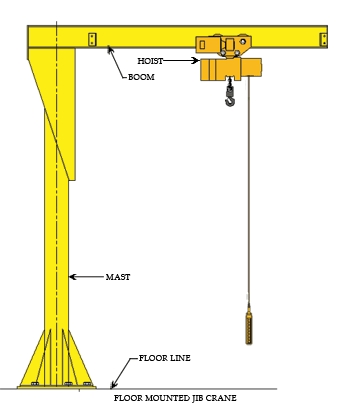

Jib Crane

Minimum Order Quantity : 10 Pieces

Material : Mild Steel

Condition : New

Application : Warehouse, Construction

Crane Type : Jib

Send Inquiry

Send Inquiry